MatchPoint BladeTM

Wood Processing System

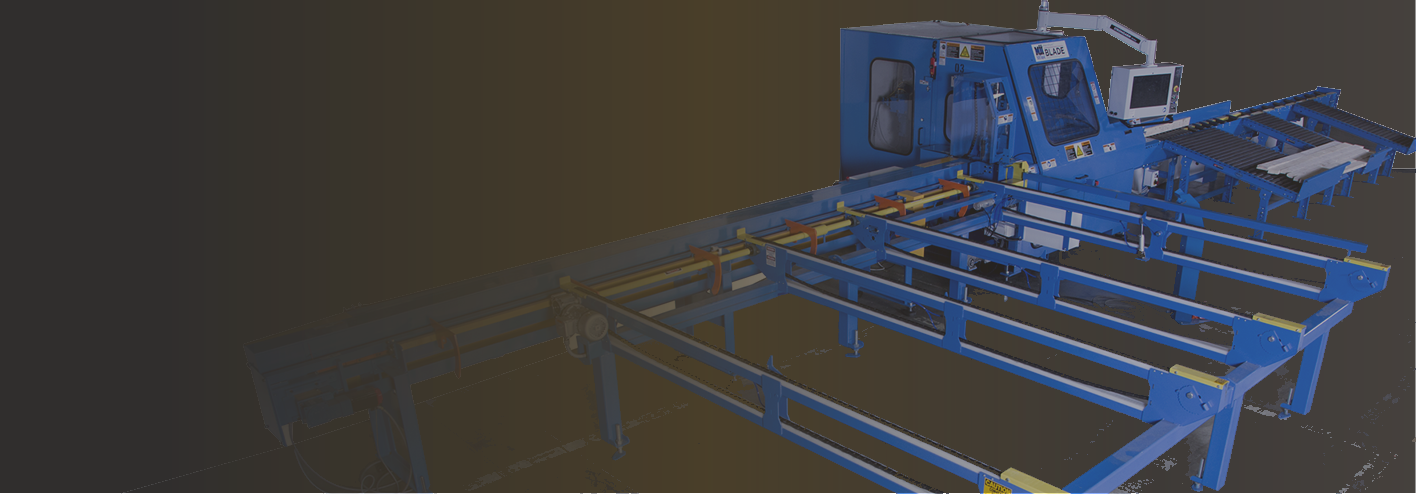

A complete wood processing system that is fast and flexible.

Features

CUTS MORE PARTS.

COSTS LESS MONEY.

- FAST – Cuts and processes parts faster than anything on the market.

- FLEXIBLE – It can fit right in to your current processes or completely change how you do business…it’s your choice!

- AUTOMATED – Automate this system as much or as little as you need.

- A COMPLETE SYSTEM – It’s a cutting device, material handling solution, and production control department all rolled into one system.

MatchPoint Blade™ Wood Processing System

Specifications

OVERVIEW

The MatchPoint BLADE™ wood processing system continues the long lineage of MiTek’s automated saws, but that’s where the normalcy stops. Everything about this saw, from its first inception, has been done differently – different for MiTek and different for the industry as a whole.

We refer to the overall piece of equipment as a wood processing system because:

- It is management system.

- It is a material handling system.

- It is a communication and organization system.

- It is a method of improving employee-to-production ratios.

- It is a computer that does all the hard thinking for you.

- It is a material conservation device (a tree-saver).

But in the center of all that, it is still a saw blade that cuts lumber to the exact specification needed at the exact time needed. And so, we affectionately call it the BLADE™.

SPEED

The simplest way to raise productivity is with machine speed. Because this is a wood processing system for the entire front end of your building process, and not just a saw, speed has many factors. All of these factors are important in realizing productivity gains and avoiding bottlenecks.

How fast the lumber can be loaded on the Auto Deck staging conveyor

- The maximum speed of the Infeed Rail gripper

- How fast the printer can print data for every part

- How fast the saw blade can make angle, bevel, stroke, and elevation changes

- The speed of the outfeed mechanism

How easily the operator and off-loader can keep up with the system.

COST AND MAN-HOUR REDUCTION

Speed of the system is one of the most important and most talked-about specifications on any equipment, but don’t forget that people are a very important part of this process. How the system affects people’s roles can add to or subtract from the total time it takes to complete a job.

- When used with the automated material handling system, it requires only one operator, providing you with a low man-hour count. That could result in ¼ to ½ your previous personnel costs on your go-to saw.

- Building “truss-by-truss” doesn’t have to be a slow, overwhelming task anymore. The printer capabilities paired with the job import options in the software make cutting single trusses just as fast as small batches on a component saw.

- A design that makes maintenance easier saves unscheduled man-hours.

- Printers on saws aren’t exactly new ideas. But the capabilities of the BLADE printer far exceed anything you’ve called a printer before.

- The lumber can be easily loaded onto the lumber feed system while the previous job is in process. If using the semiautomatic Auto Deck, pneumatic lumber stops keep the lumber for the current job separate from the lumber for the next job. If using the Ranger RS™ lumber retrieval system, bulk lumber can be loaded into their stations at any time.

FLEXIBILITY

The flexibility of the MatchPoint BLADE™ wood processing system may be its most valuable and, yet, underrated feature. Because every plant has different customers and truss demographics, every plant has different processes that work for them.

It can be installed and productive within a matter of days. You can continue business as usual, but with a newer, faster, more reliable saw and material handling system. But… why continue business as usual when you can do business better?

Using the flexibility of the MatchPoint BLADE, it may be possible to boost your production processes and your profit margins. The variety of solutions available require a conversation with your MiTek representative to fully understand the possibilities for your business.

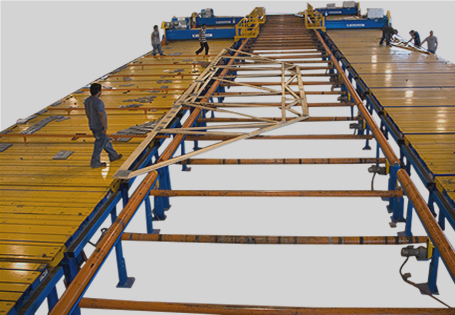

Many truss manufacturers are already enjoying the benefits of automated jigging, but are not realizing the full benefit because they are still cutting in batches. Now that you can quickly assemble in truss-to-truss manufacturing, you need a saw that can cut like that.

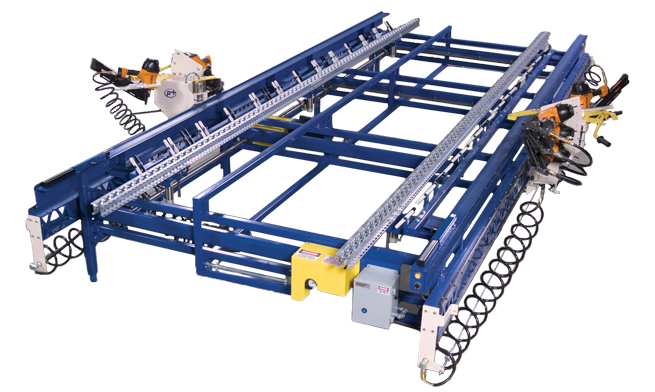

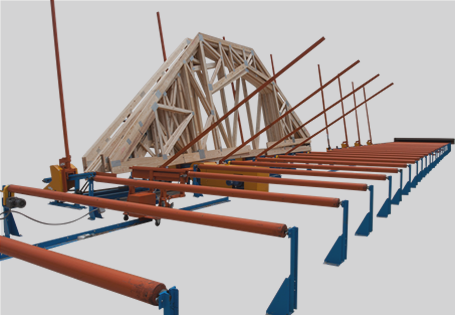

OUTFEED CAPABILITIES

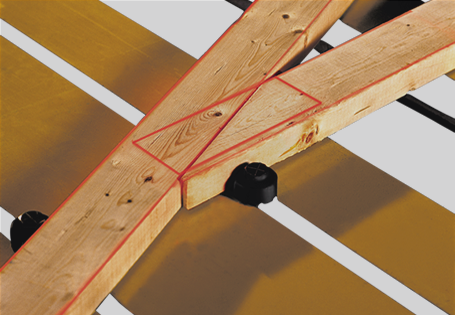

The outfeed portion of this system includes an outfeed clamp that assists in holding long boards while cutting occurs. The board is then grabbed by the lumber exit chain and pushed onto the outfeed table or automated equipment.

For a more automated option, replace the standard outfeed table with a Powered Skewed Conveyor. Or take it a step further with the Direct Drive CDS to deliver each part to your assembly tables automatically.

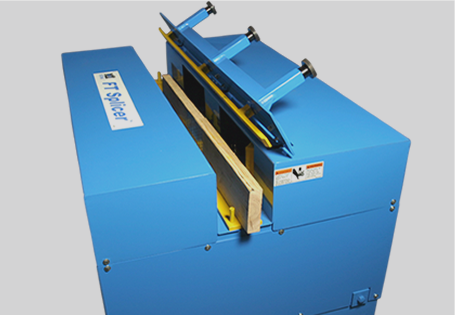

PRINTERS

The BLADE can speed up production at your assembly tables and increases efficiency at the saw. Never hand mark again. And if you are already using a printer, have you ever wished you had more room to print more information? All guesswork can be taken out of the equation for the assemblers with the right information on each part.

The standard face printer marks the cut pieces so your assembly crews know just where the pieces go in the truss configuration.

- The optional second face printer can use AGS software to mark plate location and just about any data stored in the truss design file which helps reduce plating errors at the assembly tables.

- For wall panel operations, there is an optional third printer that marks wall panel stud information on the top edge to improve productivity at your wall panel stations.

When combining all factors, the MatchPoint BLADE will outperform anything else on the market today and for years to come.

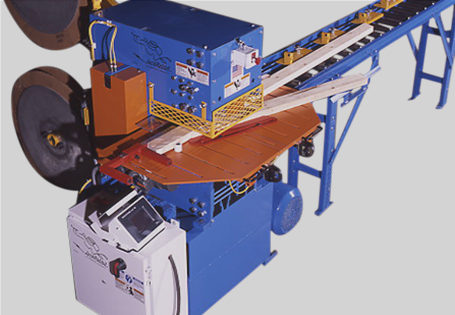

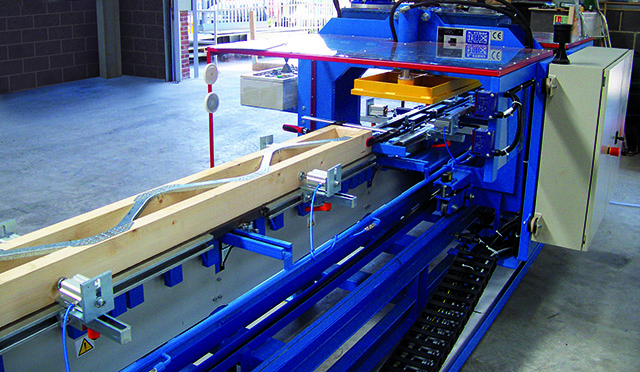

OPERATOR INTERFACE

The operator interface or HMI (human-machine interface) for the saw operator is a Windows-based touch screen computer enclosed in a touch screen enclosure which is connected to the saw with an industrial-strength, fully adjustable arm. The arm is adjustable in every direction giving the operator a clear view inside the saw chamber.

The computer accepts a keyboard or mouse attachment, but the overall HMI is designed so a keyboard and mouse are not needed.

Because the BLADE is a wood processing system, a single HMI controls more than just cutting. Most material handling equipment that bring lumber to or away from the saw can also be controlled from the BLADE HMI.

There are several different software applications in use when using the MatchPoint BLADE system.

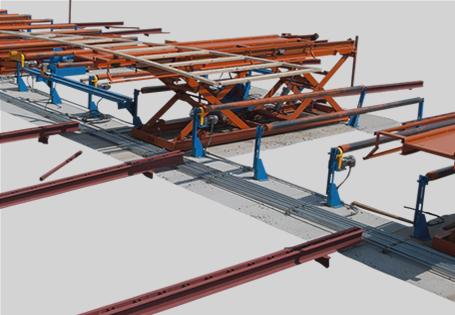

MATERIAL HANDLING

Material Handling is an easy and affordable place to raise the overall automation level in any facility.

To satisfy the ability to incrementally automate when and where each customer desires, the MatchPoint BLADE™ wood processing system gives you some options.

- On the infeed end, the Auto Deck staging conveyor is a semi-automatic easy-to-use chain conveyor. An operator loads the lumber in the correct order onto the Auto Deck conveyor, and the system takes over from there.

- The lumber for the next job can be loaded while the previous job is in process. The two jobs are kept separate by using the pneumatically controlled lumber stops.

- To fully automate the infeed process, opt for the Ranger RS™ lumber retrieval system. As long as the lumber stations are stocked, it picks the correct lumber in the correct order and gets it to the saw’s Infeed Rail.

After each part is cut, it exits through the outfeed assembly and travels to the outfeed table where an operator offloads it to be taken to the assembly tables.

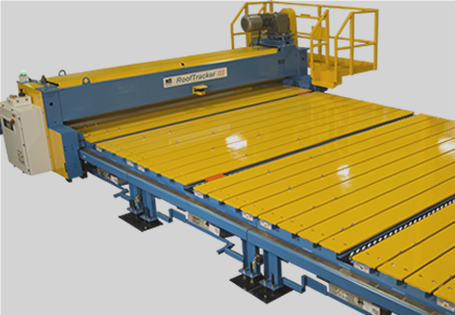

- A Powered Skewed Conveyor can be used instead of the standard outfeed table to further automate the outfeed and sorting process. The Powered Skewed Conveyor funnels cut parts to one of several different chutes. It is held there until offloaded as a group.

- The CDS is a component delivery system that is one of the offerings in the Direct Drive line of equipment. It raises the level of outfeed automation by delivering each part to the assembly tables without manual sorting needed.

DOWNLOAD THE FULL SPEC SHEET

Download PDFCUSTOMER TESTIMONIAL

“DOUBLED THE CAPACITY”

“The capacity compared to our old saws…has at least doubled. There are no bad cuts and it keeps going and going and going. The BLADE saw are reliable!” – Nick Gutierrez, Accurate Housing Systems – Troy, WI.

MACHINERY SUPPORT & RESOURCES

MiTek offers consulting, testing, documentation, design assistance and prompt customer service. Visit our Support, Training and Knowledge Base center for more information.

MACHINERY EQUIPMENT

View more of the most complete, reliable, and productive component manufacturing equipment in the industry.